Contact Kulzer International

PalaXtreme®

Strong choice. Tough dentures.

PalaXtreme – high-impact, self-curing denture acrylic for special applications

A strong base is key to a long-lasting and high-quality denture: PalaXtreme offers a unique combination of benefits to achieve this goal.

With PalaXtreme you get high-impact strength and excellent handling characteristics. The “core shell technology” minimises the risk of fractures. Due to it’s high viscosity this high-impact denture acrylic works perfectly with the pouring or the injection technique.

Benefits

- Designed for special applications such as implant based dentures

- Adds to the prevention of impact damage and therefore avoidance of time-consuming warranty repairs

- Its unique formulation offers a broad range of processing options, with injection and pouring techniques

- Low level of residual monomers: 1.4%1

- Various gingiva colour options (known Pala shades) and a clear colour option are available

1Source of Data: Sample value of PalaXtreme. Research & Development, Kulzer Wehrheim, unpublished data. Data on file.

Indications

- Implant supported dentures

- Full dentures

- Partial dentures: several or single saddles

- Dental splints

Pala Acrylics Safety video

Safety measures when working with denture acrylic materials

When using denture acrylics, work safety and the correct product application is key. In our video, we show you what you need to consider from preparation to processing to post-work.

Science

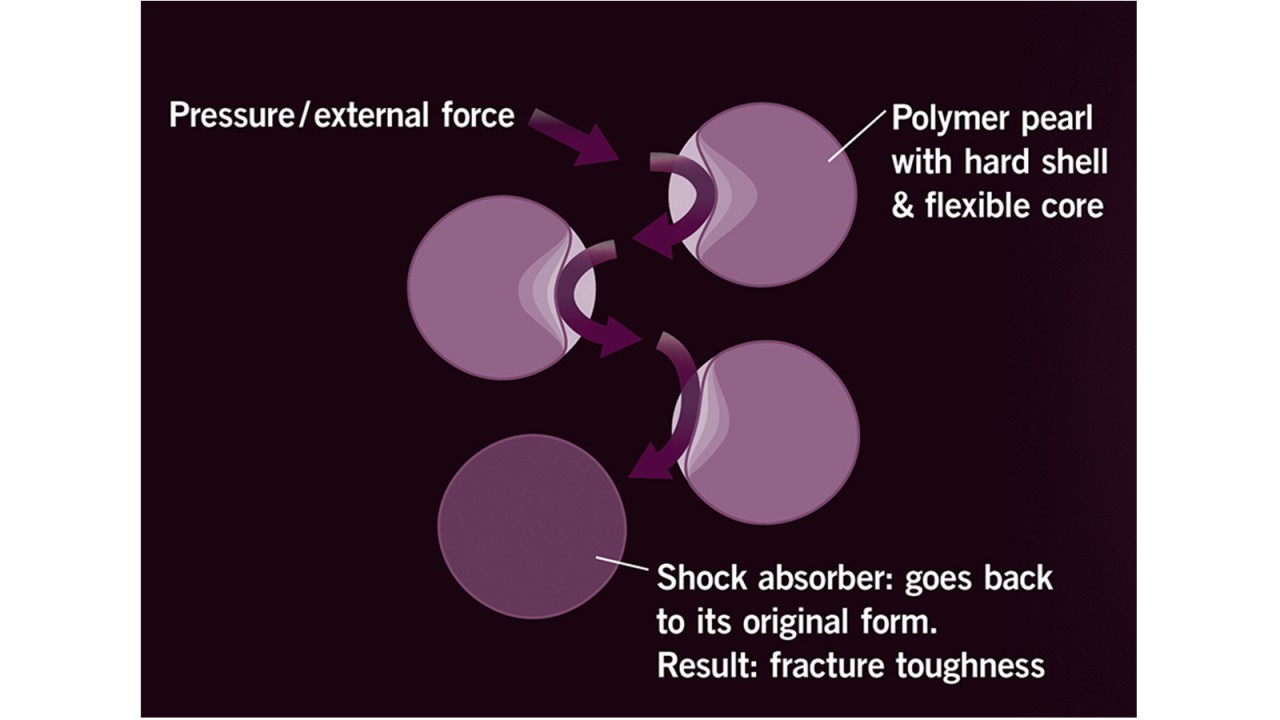

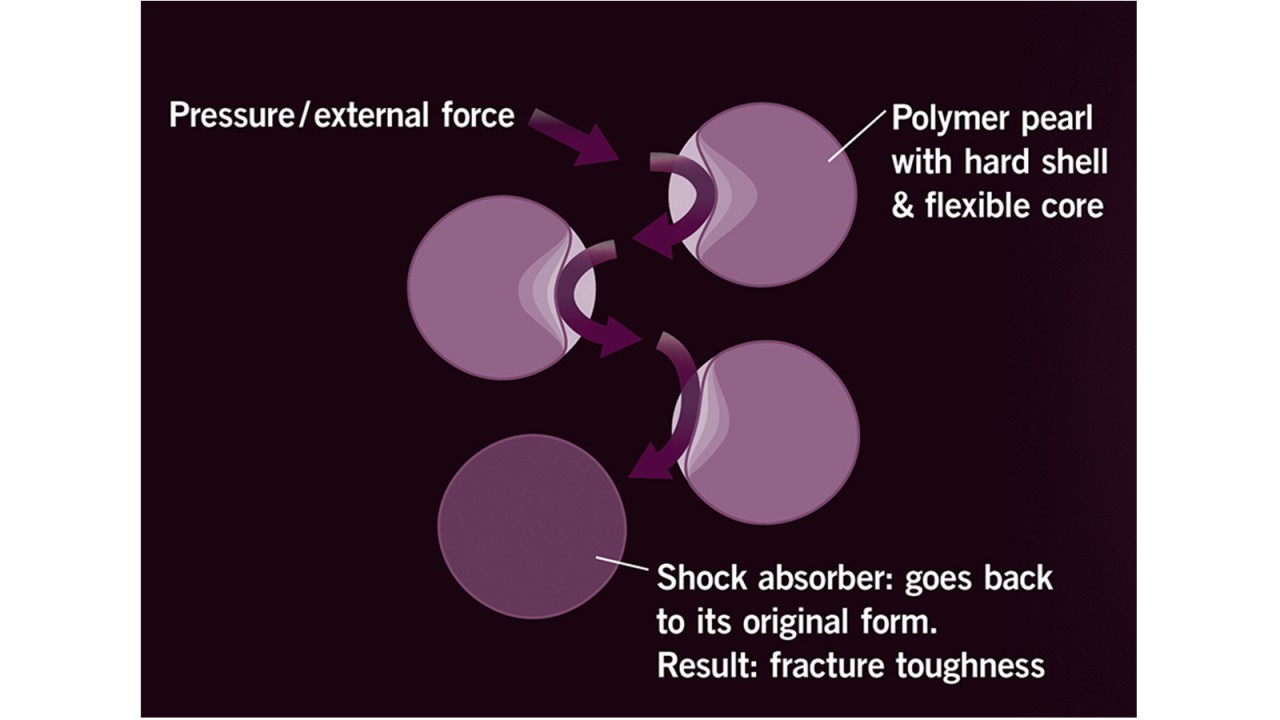

Core Shell Technology – What is it?

PalaXtreme gets its fracture toughness from the new “core shell technology” – polymer pearls with a flexible core. The flexible core prevents the pearl from breaking and acts as a shock absorber to prevent any microscopic damage from spreading to other pearls.

Fracture toughness, fracture work & colour stability

PalaXtreme is one of the first denture acrylics to exceed both of the pass/fail durability tests of ISO 20795 for maximum stress intensity (2.6 MPa*m)1 and total fracture of work (1,128 J/m²)1. This high fracture toughness is based on the “Core Shell Technology” – polymer pearl with a hard shell and a flexible core.

1Source of Data: Sample value of PalaXtreme. Research & Development, Kulzer Wehrheim, unpublished data. Data on file.

Specifications

Delivery form:

Shades: pink, pink opaque, pink veined, R50 veined, pink live, clear

Powder: 100g, 1,000g and 12,000g

Liquid: 80ml, 500ml