Contact Kulzer International

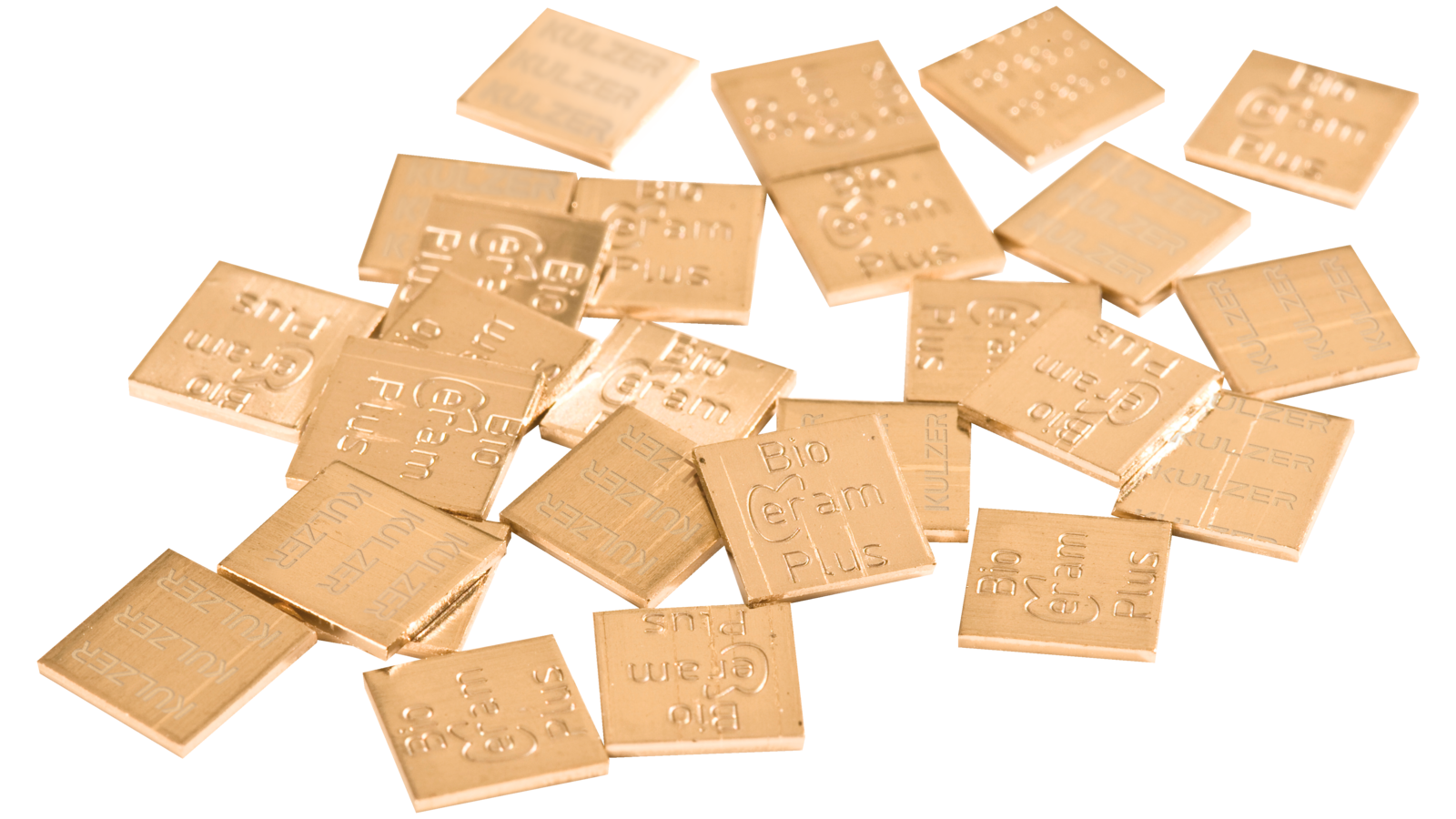

Bio Ceram Plus® - for C& B

High gold content ceramic bonding alloy acc. to EN ISO 9693-1 and 22674, deep yellow

Benefits

- Unique gold shades

- Easily polished

- Palladium and copper free

- Gold content: 90.%

- Very high precious metal content 98.15%

- Very good thermal shock resistance

- Wide indication range

- Perfectly matched to HeraCeram

Indications

- Single crowns

- Bridges

- Milling procedures

- Implants

Specifications

| Technical specifications, melting and casting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Melting range | 1040° - 1100° C | |||||||||||||

| Preheating temperature | 850 ° C | |||||||||||||

| Casting temperature | 1250 ° C | |||||||||||||

| Crucible | Graphite | |||||||||||||

| Density | 19.0 g/cm3 | |||||||||||||

| Hardness (HV5) | 220 (w/k), 220 (v), 180 (s) | |||||||||||||

| 0.2 % yield strength (MPa) | 520 (w/k), 520 (v) | |||||||||||||

| Elongation (%) | 3 (w/k), 3 (v) | |||||||||||||

| Young's modulus of elasticity (GPa) | 87 | |||||||||||||

|

Ceramic bonding alloy acc. to EN ISO 9693, EN ISO 22674 |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | 4 (s/ v/ k) | |||||||||||||

| Shade | dark yellow | |||||||||||||

| Indication | 3,4,5,15A) | |||||||||||||

|

Composition |

Au 90.0 Pt 7.9 Zn 1.5 Ir x Fe 0.1/ Mn 0.1/ Rh 0.2/ Nb 0.1/ Ce x |

|||||||||||||

| Ceramic firing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CTE | 14.7 | |||||||||||||

| Oxide firing | 880° C/ 10 min. (vacuum, stripping) | |||||||||||||

| Soft annealing | --- | |||||||||||||

| Hardening | ---° C/ --- min. | |||||||||||||

| Solder/laser welding wire | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solder |

Herador PF solder 1010 Herador/Maingold PF solder 800 |

|||||||||||||

| Laser welding wires | Ø 0.5 mm x 200 mm + Ø 0.3 mm x 200 mm | |||||||||||||

Specification legend

Explanation of abbreviations and numbering:

x = content < 0.1 mass%

Indications:

1 Inlays, cervical filling

2 MOD Inlays

3 Crowns

4 Bridges

5 Milling technique

6 Partial dentures

10 Cast posts

14 Can be veneered with high expansion, low-fusing ceramics

15 Implant restorations

16 Electroformed double crown technique (primary crowns)

Abbreviations:

w = after soft annealing and quenching

k = ceramic bonding alloy: condition after ceramic firing

v = after hardening

s = self-hardening after slow cooling in the mould

A = A stable framework design with reinforced connections with a cross section of 8 - 10 mm² is required for long span bridges and superstructures. Additionally, the frameworks need to be hardened.

B = Depending on the copper content, in some cases discolouration ofdouble crowns may result after short period of wearing. Discolouration, however, is technically and physiologically harmless.

C = In exceptional cases these alloys can also be used for traditional telescopic crowns with parallel walls and for the bar casting technique provided that cross-sections for crown walls, approximal areas, bars and laser welded joints are particularly thick and the alloy is hardened subsequently. No indication for conical crowns and sheardistributors.

Please observe instructions for use included during delivery when processing of the alloy!